Turner Technology: Revolutionizing Industries and Enhancing Efficiency

Turner Technology is a game-changer in the manufacturing sector that is setting new standards for excellence. So buckle up as we dive deep into understanding how Turner Technology transforms industries and enhances efficiency like never before!

nnnnTurner Technology Overview

nnnn

At its core, Turner Technology is a leading manufacturing company disrupting industries with its innovative approach. With a strong focus on cutting-edge technology and unparalleled expertise, Turner Technology has positioned itself as a trailblazer in the field.

nnnnIts commitment to pushing boundaries and challenging traditional methods sets Turner Technology apart from its competitors. The company’s forward-thinking mindset constantly drives it to explore new possibilities and seek unconventional solutions.

nnnnOne of the critical pillars of Turner Technology’s success lies in its ability to adapt quickly to changing market demands. By staying at the forefront of technological advancements, they can anticipate industry needs and provide tailored solutions that exceed expectations.

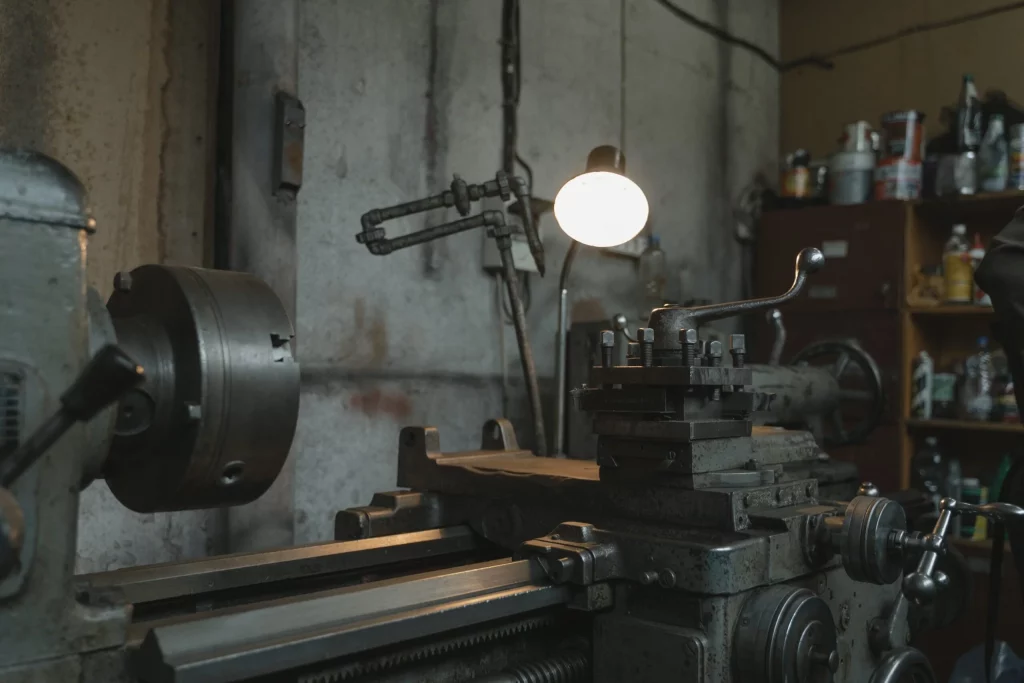

nnnnMoreover, Turner Technology takes pride in its state-of-the-art facilities with advanced machinery and tools. It enables them to deliver high-quality products efficiently while maintaining strict quality control standards throughout manufacturing.

nnnnWith an unwavering dedication to customer satisfaction, Turner Technology goes above and beyond by offering comprehensive support services. From initial concept development to final product delivery, their team of experts ensures seamless collaboration every step of the way.

nnnnTurner Technology is an industry leader due to its relentless pursuit of innovation, adaptable nature, cutting-edge manufacturing capabilities, and unparalleled customer support. It is no wonder why businesses across various sectors are turning towards this revolutionary company for their manufacturing needs.

nnnnTurner’s Unique Approach to Manufacturing

nnnnTurner Technology takes a unique approach to manufacturing that sets them apart from their competitors. Unlike traditional manufacturing processes, Turner utilizes cutting-edge technology and innovative techniques to deliver superior results.

nnnnOne aspect of Turner’s unique approach is its emphasis on precision and accuracy. They utilize advanced software and automation tools to ensure that every product they manufacture meets the highest quality standards. It not only improves efficiency but also reduces the margin for error, resulting in consistently reliable products.

nnnnAnother critical element of Turner’s approach is its commitment to customization. They understand that each industry has specific needs and requirements, so they work closely with clients to develop tailored solutions. Whether it’s designing specialized parts or creating entirely new products from scratch, Turner excels at delivering customized solutions that meet the unique demands of their clients.

nnnnAdditionally, Turner embraces sustainability in their manufacturing practices. They prioritize environmentally friendly materials and processes whenever possible, helping businesses reduce their carbon footprint without compromising performance or reliability.

nnnnTurner’s unique approach to manufacturing combines advanced technology, customization, and sustainability to provide exceptional results for industries across the board. By staying ahead of the curve and constantly innovating, they continue to revolutionize the way products are made while enhancing efficiency for their clients.

nnnnHow Turner Technology is Revolutionizing Industries

nnnnTurner Technology is making waves in various industries by revolutionizing traditional manufacturing processes. With its cutting-edge technology and innovative solutions, Turner has become a game-changer in the industry.

nnnnOne way that Turner Technology is transforming industries is through automation and robotics. By implementing advanced robotics systems, Turner can streamline production processes and increase efficiency. It saves time and reduces human error, leading to higher-quality products.

nnnnAdditionally, Turner’s use of artificial intelligence (AI) has revolutionized business operations. AI-powered algorithms analyze large amounts of data to identify patterns and optimize manufacturing processes. It allows companies to make more informed decisions and improve overall productivity.

nnnnAnother area where Turner Technology excels is additive manufacturing, also known as 3D printing. This groundbreaking approach allows for creating complex designs with precision and speed. It eliminates many traditional constraints associated with conventional manufacturing methods, enabling companies to develop highly customized products efficiently.

nnnnMoreover, Turner embraces sustainability by incorporating eco-friendly practices into its manufacturing processes. By utilizing recyclable materials and minimizing waste generation, they reduce their environmental impact while delivering exceptional client results.

nnnnTurner Technology’s revolutionary approach to manufacturing is reshaping industries across the board. Through automation, AI integration, 3D printing capabilities, and sustainability efforts,

nnnnTurner continues to enhance efficiency while pushing boundaries in innovation.

nnnnBy leveraging these technologies,

nnnncompanies can stay ahead of their competition

nnnnand unlock new possibilities for growth

nnnnin an increasingly digital world

nnnnHow Turner Technology is Enhancing Efficiency

nnnn

One of the critical ways that Turner Technology is revolutionizing industries is by enhancing efficiency in various processes. Their innovative solutions and cutting-edge technology are streamlining operations and maximizing productivity.

nnnnTurner’s approach to manufacturing is unique and forward-thinking. They leverage state-of-the-art automation systems to optimize production lines and eliminate inefficiencies. Integrating their advanced software with machinery enables real-time monitoring, data analysis, and process optimization.

nnnnThrough their intelligent manufacturing solutions, Turner Technology empowers companies to achieve higher levels of efficiency. Their intelligent systems can anticipate maintenance needs before breakdowns occur, reducing downtime and increasing overall equipment effectiveness.

nnnnAdditionally, Turner’s technology enables seamless connectivity across different stages of the production cycle. This integration allows efficient communication between machines, ensuring smooth coordination and minimizing delays or errors.

nnnnAnother aspect where Turner enhances efficiency is its commitment to sustainability. Implementing energy-saving measures and eco-friendly practices into their technology solutions helps businesses reduce waste while optimizing resource utilization.

nnnnTurner Technology’s impact on efficiency is undeniable. Through their innovative approach to manufacturing processes and dedication to sustainability practices, they are setting new standards for productivity enhancement in various industries.

nnnnConclusion

nnnnTurner Technology is truly a game-changer in the manufacturing industry. Their unique approach and cutting-edge solutions are revolutionizing industries and enhancing efficiency like never before.

nnnnTurner Technology can deliver exceptional results by integrating advanced technologies such as robotics, artificial intelligence, and data analytics into their manufacturing processes. Their ability to automate tasks that were once time-consuming and prone to human error has increased productivity and cost savings for businesses across various sectors.

nnnnFurthermore, Turner’s commitment to continuous improvement ensures they stay at the forefront of technological advancements. They constantly strive to refine their processes and explore new innovative solutions, enabling them to provide even greater value for their clients.

n