One common type of scraper used in conveyors is known as a primary or pre-cleaner scraper. Positioned at the head pulley where the belt starts its journey, the conveyor belt scraper removes large chunks and coarse materials that may have adhered to the belt during the loading processes. Its robust construction allows it to withstand heavy-duty tasks while ensuring optimal performance.

In addition to primary scrapers, some systems also employ secondary or tertiary scrapers. These are located further down the conveyor line and focus on finer particles left behind by the primary scraper. The integration of multiple scrapers ensures thorough cleaning throughout the entire length of the belt.

Furthermore, modern advancements have brought about innovative scraping solutions such as automatic tensioning systems which enhance productivity and reduce manual labor required for maintenance. With technology rapidly evolving within this field, conveyors are becoming more efficient than ever before with scraping mechanisms designed for precision cleaning and longevity.

In summary, scrapers are indispensable components in conveyor systems that help maintain operational efficiency by preventing material build-up and reducing equipment wear. Their design intricacies cater specifically to various circumstances faced within industries such as mining, agriculture, or manufacturing

Types of scrapers used in conveyors

Scraper systems are an essential component of conveyor systems and play a crucial role in maintaining the efficiency and cleanliness of the conveyors. There are various types of scrapers used in conveyors, each designed to cater to specific requirements.

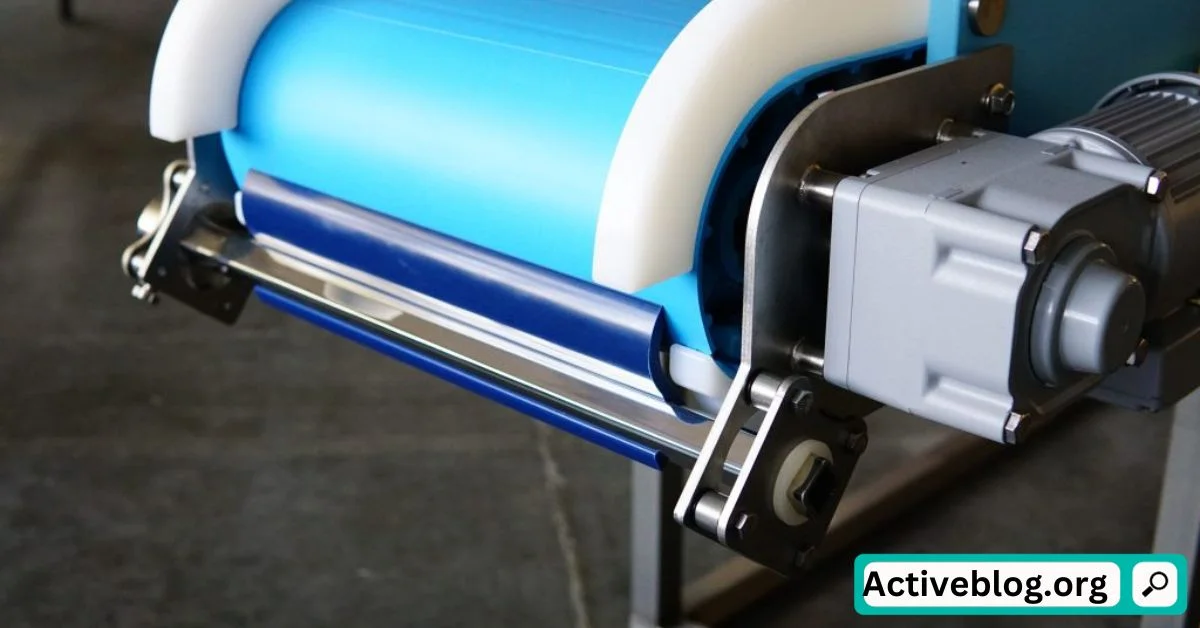

One commonly used type is the belt scraper, which is installed on the head pulley near the discharge end of the conveyor. This scraper ensures that material does not accumulate on the surface of the belt and helps prevent spillage. Belt scrapers can be either primary or secondary, with primary scrapers being more robust and efficient in removing bulk materials.

Another type is the brush scraper, which utilizes bristles made from synthetic materials or natural fibers. These brushes gently sweep away any fine particles or residue that may have adhered to the belt surface. The bristles can be flexible or stiff depending on specific application needs.

Click here to read more conveyor belt accessories

In addition to these two types, there are also blade scrapers commonly used in conveyors for heavy-duty applications. These motorized devices use a conveyor belt scraper rotating blade to effectively remove stubborn build-up from belts or pulleys. Blade scrapers are highly durable and offer reliable performance even in harsh environments.

Overall, understanding the different types of scrapers available for conveyor systems allows businesses to choose one that best suits their operational needs. Whether it’s preventing spillage, cleaning fine debris, or tackling tough residues, selecting an appropriate scraper can significantly enhance productivity while reducing maintenance downtime for conveyor systems.

Importance of using scrapers in conveyors

The importance of using scrapers in conveyors cannot be overstated. These small yet powerful components play a crucial role in maintaining the efficiency and productivity of conveyor systems. One of the main functions of a scraper is to remove material from the belt, ensuring that it does not accumulate or cause blockages along the conveyor’s path. This prevents downtime and enhances operational reliability.

In addition to preventing blockages, scrapers also contribute to cost savings by minimizing spillage. When materials are transported on a conveyor belt, there is always some level of spillage that occurs. However, with effective scraper systems in place, this spillage can be significantly reduced or eliminated altogether. By keeping the belt clean and free from material build-up, scrapers help to minimize waste, improve product quality, and reduce cleanup costs.

Moreover, scrapers can have a positive impact on workplace safety. Accumulated material on conveyor belts poses various hazards ranging from slip-and-fall incidents for workers to potential damage to equipment due to increased friction and wear. By removing excess material promptly and efficiently, scrapers enhance safety by reducing these risks and creating a safer working environment.

Overall, using scrapers in conveyors is essential for optimal performance, cost-effectiveness, and environmental sustainability as well as ensuring the safety of workers and machinery alike. Neglecting this crucial component can lead to issues such as inefficiency, and higher maintenance costs. Increased waste generation, and compromised safety standards within an industrial setting. Therefore investing in quality scrappers should be prioritized

Conclusion: Importance of proper scraper usage

Proper scraper usage is crucial in maintaining the efficiency and longevity of conveyor systems. While often overlooked. Scrapers play a vital role in removing material residue from the conveyor belt, preventing build-up that can cause blockages and decrease productivity. By ensuring that scrapers are correctly installed and adjusted, companies can conveyor belt scrapers minimize downtime and reduce maintenance costs.

One key benefit of using scrapers effectively is improved material containment. A well-functioning scraper helps to keep bulk materials contained within the conveyor system, minimizing spillage and reducing environmental impacts. This is particularly important for industries handling hazardous or volatile substances as it ensures worker safety and prevents contamination. Additionally, proper scraper usage also contributes to a cleaner working environment by preventing dust emissions. Which not only improves employee health but also reduces regulatory compliance issues.

Furthermore, proper scraper usage enhances overall system efficiency by optimizing energy consumption. When residues accumulate on the belt surface, they increase friction between the belt and pulleys, leading to higher power consumption. By regularly cleaning the belt with an effective scraper, companies can reduce energy waste and ultimately save on operational costs. Additionally, reduced friction results in less wear and tear on conveyor components such as belts and rollers, extending their lifespan and reducing replacement expenses.

In conclusion, although often overlooked or undervalued in conveyor systems’ maintenance procedures. Proper scraper usage is essential for maximizing efficiency while minimizing downtime and maintenance costs. From improving material containment to enhancing energy efficiency levels; utilizing scrapers correctly offers multiple benefits for businesses across different industries. Incorporating regular inspection